16 September 2025

The global market for artificial grass solutions, including wholesale grass carpet, is experiencing robust growth driven by increasing demand for sustainable, low-maintenance, and aesthetically pleasing landscaping alternatives. Historically, natural turf presented significant challenges related to water consumption, pest control, and consistent upkeep. Modern artificial turf, often seen as an artificial carpet or specialized artificial garden mat, addresses these issues by offering superior durability and reduced operational costs. This shift is particularly evident in commercial applications, sports facilities, and public spaces where consistent visual quality and cost-efficiency are paramount. Industry trends indicate a strong focus on eco-friendly materials, advanced drainage systems, and enhanced fiber technologies that mimic the look and feel of natural grass with unprecedented realism.

Technological advancements in polymer science and manufacturing processes have led to the development of highly resilient and UV-resistant fibers, making artificial grass an increasingly viable option across diverse climates. Furthermore, the versatility of these products extends beyond traditional landscaping to specialized uses such as an artificial grass aisle runner for events, or even an artificial grass bedroom carpet for unique interior design concepts. As manufacturers continue to innovate, incorporating features like anti-bacterial coatings and improved shock absorption, the adoption rate of artificial grass carpet products is projected to accelerate, offering sustainable solutions for urban environments and beyond. The market is segmented by pile height, material composition (e.g., polyethylene, polypropylene, nylon), and specific application, allowing for tailored solutions that meet precise client requirements.

Our flagship product, Carpet Grass CG15, represents a significant leap in artificial turf technology. Designed with precision engineering, CG15 enhances sports performance and visual effects while dramatically improving durability and stability. This is achieved by upgrading the height and density of grass fibers, creating a denser, more resilient surface that withstands intensive use. The unique fiber structure of CG15 ensures consistent ball roll and reduced friction, critical factors in professional sports applications. Beyond sports, CG15 is an ideal choice for high-traffic commercial landscapes, public parks, and event spaces where an area rug that looks like grass is desired for both aesthetic appeal and practical performance.

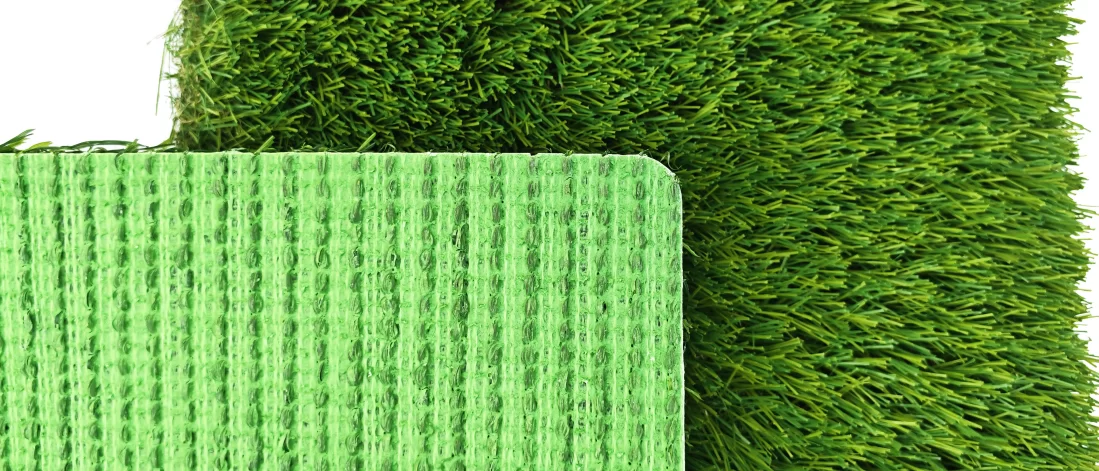

The technical specifications of Carpet Grass CG15 are meticulously calibrated to deliver superior performance. Its enhanced pile height (typically 40-50mm) combined with a high Dtex (decitex) rating for the yarn ensures excellent resilience and a natural, plush feel. The backing system, often a robust triple-layer poly-urethane or SBR latex, provides exceptional dimensional stability and drainage capabilities. These attributes make CG15 an optimal solution for projects demanding the highest standards in both functionality and longevity. Whether used as a comprehensive artificial garden mat or a premium artificial grass carpet for commercial properties, its advanced design guarantees a pristine look and consistent performance for years, reducing the need for costly maintenance.

Understanding the precise technical parameters is crucial for B2B decision-makers. Below is a comparative table highlighting the key specifications of our Carpet Grass CG15 against a typical market-standard artificial turf product. This data underscores CG15's superior design and engineering, demonstrating why it's a preferred choice for demanding applications requiring a robust wholesale grass carpet solution.

Parameter | Carpet Grass CG15 | Standard Artificial Turf |

Fiber Material | Advanced Polyethylene (PE) + Polypropylene (PP) blend | Polyethylene (PE) |

Pile Height | 40mm – 50mm | 25mm – 35mm |

Dtex (Yarn Weight) | 12,000 – 15,000 | 8,000 – 10,000 |

Gauge | 3/8 inch | 3/8 or 5/8 inch |

Stitches/m² | 18,000 – 22,000 | 12,000 – 15,000 |

Backing | Triple-layer SBR Latex / PU | Double-layer SBR Latex |

UV Resistance (Years) | 8-10+ | 5-7 |

Drainage Rate | 1200mm/hr (per m²) | 800-1000mm/hr (per m²) |

Certification | ISO 9001, ISO 14001, FIFA Quality (selected variants) | ISO 9001 |

This comparison clearly illustrates CG15's superior structural integrity, higher density, and robust material composition, leading to enhanced longevity and performance in demanding environments, making it an excellent choice for a durable artificial grass carpet.

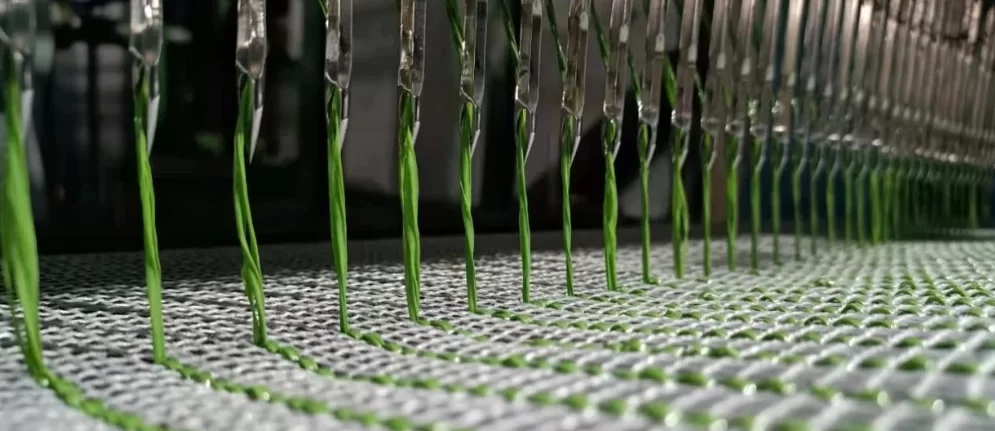

The production of high-quality artificial carpet involves a sophisticated multi-stage manufacturing process, ensuring consistency, durability, and aesthetic appeal. This journey begins with the selection of premium polymer resins, typically polyethylene (PE) or polypropylene (PP), which are rigorously tested for UV stability, tensile strength, and environmental safety. The raw materials are then subjected to a specialized extrusion process where they are melted and forced through a die to form fine, consistent synthetic fibers. These fibers are then textured and often given a specific shape (e.g., C-shape, V-shape, W-shape) to enhance resilience and natural appearance. This meticulous process ensures that each strand of artificial grass carpet meets stringent quality control standards before advancing to the next stage.

Following fiber extrusion, the tufting stage is critical. Here, thousands of these individual fibers are threaded through a primary backing material, typically a woven polypropylene fabric, using specialized tufting machines. The fibers are "tufted" in precise patterns to create the desired pile height and density, characteristic of a lush artificial garden mat or a robust wholesale grass carpet. After tufting, the primary backing is coated with a secondary layer, commonly SBR latex or polyurethane. This coating securely binds the fibers to the backing, providing exceptional dimensional stability, tear resistance, and crucial drainage properties. The material then undergoes a curing process, often in high-temperature ovens, to solidify the backing. Finally, the finished turf is inspected for quality, trimmed, and rolled for packaging and shipment. Adherence to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management is strictly maintained throughout this entire manufacturing chain, ensuring product reliability and environmental responsibility for every artificial grass bedroom carpet or large-scale installation.

The versatility of artificial grass carpet makes it suitable for an expansive range of applications across various industries. In the sports sector, high-performance variants like Carpet Grass CG15 are integral for football fields, golf courses, and multi-sport complexes, providing consistent playability and exceptional shock absorption for athlete safety. For commercial and residential landscaping, an area rug that looks like grass offers a perpetually green, manicured appearance without the need for watering, mowing, or fertilizing – significant advantages in terms of water conservation and reduced labor costs. Its aesthetic consistency makes it ideal for public parks, rooftops, and urban green spaces, transforming concrete jungles into vibrant, sustainable landscapes.

Beyond traditional uses, customized artificial grass aisle runner solutions are increasingly popular for events, trade shows, and retail displays, providing an eye-catching and durable floor covering. Interior design also benefits from the unique textural and visual appeal of an artificial grass bedroom carpet or office flooring, bringing a touch of nature indoors without the practical challenges of live plants. The technical advantages of these products are multifaceted: superior drainage ensures rapid water dispersion, preventing puddling and maintaining usability even after heavy rainfall. UV stabilization guarantees colorfastness and prevents degradation under intense sunlight. Furthermore, their non-toxic, hypoallergenic properties make them safe for children and pets, enhancing their appeal for family-oriented environments. Our solutions are designed to be durable, typically offering a service life of 8-15 years, significantly outperforming natural grass in terms of maintenance and longevity.

While many manufacturers offer standard artificial carpet products, our expertise lies in providing bespoke solutions tailored to specific project requirements. From unique pile heights and densities for specialized sports surfaces to custom color blends for brand integration or aesthetic themes, our manufacturing flexibility ensures that every client receives a product perfectly aligned with their vision. We also offer comprehensive support for wholesale grass carpet orders, ensuring efficient logistics and installation guidance for large-scale projects. When comparing manufacturers, key differentiators include the quality of raw materials, the sophistication of the manufacturing process, adherence to international standards, and the breadth of customization options.

Our commitment to quality is underscored by our ISO 9001 and ISO 14001 certifications, reflecting our stringent quality control and environmental stewardship. Unlike some competitors who may compromise on fiber Dtex or backing quality to reduce costs, we prioritize long-term performance and client satisfaction. Our extensive service history, spanning over 15 years in the artificial turf industry, coupled with collaborations with renowned landscape architects and sports federations, solidifies our position as an authoritative provider. We provide detailed test data for our products, including wear resistance, UV stability, and drainage rates, offering complete transparency and building trust with our B2B partners seeking reliable artificial garden mat or artificial grass carpet solutions.

Dtex (decitex) is a unit of measurement for the linear mass density of fiber, expressed as the weight in grams of 10,000 meters of fiber. For artificial grass carpet, a higher Dtex value generally indicates a thicker, more robust, and more durable fiber. This translates to better resilience, greater resistance to flattening, and a longer lifespan, particularly important for high-traffic areas or sports applications. Carpet Grass CG15, with its high Dtex rating, exemplifies superior fiber quality and longevity.

The primary materials are synthetic polymers: Polyethylene (PE) for softness and natural feel, Polypropylene (PP) for stiffness and resilience, and Nylon for exceptional durability in specific applications. The backing is typically made from woven polypropylene and then coated with SBR latex or polyurethane for structural integrity and drainage. These materials are chosen for their durability, UV resistance, and environmental safety, forming the core of any quality artificial carpet.

High-quality artificial garden mat products feature perforated backing that allows water to drain through the turf at rates exceeding 1000mm per hour per square meter. This water then flows into a prepared sub-base, typically consisting of crushed rock and aggregate, which is designed to facilitate rapid percolation into the ground or a dedicated drainage system. Proper installation of the sub-base is critical for effective drainage and preventing water accumulation.

Installation standards for an area rug that looks like grass or a full-scale field involve several steps: site preparation (clearing, grading), compaction of the sub-base (often gravel or crushed stone), laying a weed barrier, rolling out the turf panels, seaming them together with adhesive tape and specialized glue, infilling with sand or rubber granules (for stability and performance), and final grooming. Adherence to manufacturer guidelines and industry best practices is crucial for longevity and performance.

The lifespan of a wholesale grass carpet varies depending on the quality of the product, the intensity of use, and local climate conditions. High-quality artificial grass, like Carpet Grass CG15, typically comes with a manufacturer's warranty of 8-10 years, but can often last 15 years or more with proper maintenance. Factors like UV exposure, foot traffic, and correct installation significantly influence its durability.

Modern artificial grass carpet is considered environmentally beneficial due to significant water savings (eliminating irrigation), reduction in pesticide and herbicide use, and elimination of noisy, polluting lawn mowers. Many products are also made from recyclable materials, and manufacturers are increasingly focusing on sustainable production methods and end-of-life recycling programs.

Our standard delivery lead time for wholesale grass carpet orders typically ranges from 2-4 weeks, depending on order volume and customization requirements. Expedited shipping options are available upon request. All our artificial turf products, including Carpet Grass CG15, come with a comprehensive 8-year limited warranty covering defects in materials and manufacturing. This warranty reflects our confidence in the longevity and quality of our solutions, ensuring peace of mind for our clients.

1. The Synthetic Turf Council. (2023). Environmental Benefits of Synthetic Turf.

2. ASTM International. (2022). Standard Specification for Infill Materials for Synthetic Turf Sports Fields. (Designation: F1015-22).

3. FIFA. (2021). FIFA Quality Programme for Football Turf. (Manual for Testing and Certification).

4. International Organization for Standardization (ISO). (2015). Quality Management Systems – Requirements. (ISO 9001:2015).

5. International Organization for Standardization (ISO). (2015). Environmental Management Systems – Requirements with guidance for use. (ISO 14001:2015).

Hit enter to search or ESC to close